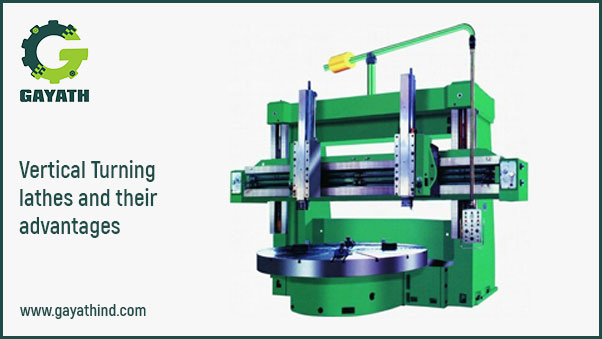

Vertical Turning lathes and their advantages

Introduction

A range of applications and technologies may seem old-fashioned but they are needed to make some of the best parts. This is very true for VTL Machining companies in Chennai in order to provide the best service for their customers. A traditional VTL is a classic example in this class of technology. However, there are newer versions of these tools and they incorporate productive technologies and innovations that are found in horizontal turning centers. Gayath Heavy Engineering Private Limited uses these disposable machines with various advantages.

Usage in a wide variety of castings

Equipment with good machining capabilities or companies that outsource the entire machining process can reap huge benefits from VTL technology. The VTL configuration mainly uses a traditional lathe for the manufacturing process. This unique design provides a wide array of production methods, and cost reduction and is particularly suitable for castings like brake discs, aircraft parts, pump housing materials, and many more.

Here are some of the advantages of VTL machining companies in Chennai

The vertical turning lathes are huge and ram-type machines. They are also called vertical boring mills or VBM. These lathes cannot produce huge quantities at the same time; however, they are ideal for cutting medium-sized or large parts and are heavy-duty.

- A major advantage of a VTL machine is it easily handles heavy workloads and pieces and can be set or held in a particular place for machining. The benefit of using VTL is only a minimum amount of hard clamping is required.

- The vertical turning lathes use a spindle or fulcrum to load and unload on their own. They have multitasking abilities and which makes them efficient processing units to produce clamps and chucked parts.

- The vertical turning lathes give the foundries a machine shop that has the ability to cut heavy and big castings.

- This tool can be indexed distinguishing it from VBM’s (Vertical Boring Machines).

- The VTL machines also use a design that rotates using a rotating table in order to support the workpiece and bridge construction to carry the X-axis.

- When it comes to productivity, the VTL improves the cycle time to a large extent and enables shops with aggressive cuts.

- In addition to these, it comes with high horse power and torque that is required to cut heavy metals that are difficult to cut otherwise.

The role of VTL in VTL Machining companies in Chennai

This machine uses a table drive system and ram that are capable of delivering high horsepower and torque used for heavy hogging. It also incorporates the advancements that are demanded by machine tool users across industries. Some of the features include thermal stability, automation, reduced set-up time, and a smaller size that occupies lesser floor space. In addition to these, they are mounted with cameras so that operators can track the operations even from remote locations.

Conclusion

VTL’s of Gayath Heavy Engineering Private Limited has always been very useful for machining companies in the large picture. This is because of gravity that enables keeping the workpiece together rather than creating an opposite effect to the clamping procedure. It is still being used by construction, marine equipment manufacturers, energy sectors, and other sectors where these machines are commonly used.